Ice cream spoons and coffee cups as sustainable to go alternatives

Since 03 July 2021, most single-use plastic products have been banned in the EU. This includes plastic straws, stir sticks, balloon sticks or disposable tableware made of conventional and bioplastic. To go cups and disposable containers made of styrofoam are also affected by the ban. The EU decision is intended to benefit the environment and protect the oceans. On the one hand, plastic products are often made from crude oil, a finite and fossil material mixture, and on the other hand, the resulting plastic waste is often not disposed of properly and thus ends up in the environment, where it hardly or only very slowly decomposes. Around 85 million tons of plastic end up in the sea every year, where it takes up to 500 years to decompose. The resulting plastic particles are eaten by marine animals and eventually find their way back into the human organism. In addition, a correlation has been established between the amount of plastic waste in the ocean and the declining fish population.

In the following, the problem of disposable products is explained using the example of to go cups: in Germany alone, up to 140 thousand to go cups are disposed of every hour. In a year, that's about 2.8 billion pieces. A classic cup consists of paper and plastic. The extraction of the raw materials and the production process consume a lot of energy and water. Every year, around 43,000 trees are felled for the production of the cups. The production of one kilogram of paper requires more than 50 liters of water. In total, the production of paper fibers consumes 320 million kWh annually. The cups alone therefore cause 83,000 metric tons of C02 emissions per year - and this does not include the caps. The effort and environmental impact of production are therefore immense. The time it takes to enjoy the coffee, on the other hand, is short. On average, it only takes 10 to 15 minutes for the cups to be disposed of after use.

The issue of sustainability is also becoming increasingly important to consumers. And with it the desire for unpackaged food.

Over 50% of Germans say it is important to them to avoid packaging waste. At the same time, the number of unpackaged stores is growing and new plastic-free alternatives are continuously coming onto the market, including firm shower gel or body lotion. In 2014, the first unpackaged store opened in Germany, and today there are already well over 100. In addition, more sustainable alternatives are also increasingly being developed in the catering and to go sector. From reusable cups to pasta straws, more and more creative solutions are being found.

Many companies are coming up with environmentally friendly solutions to disposable and reusable cutlery and containers. Not only do they want to produce plastic alternatives from renewable raw materials, but they are also developing compositions that decompose in nature and thus pose no threat to the environment and animals. At the same time, some companies are tackling resource wastage by using residual materials from the food industry, thus creating a sustainable circular economy. Another promising consideration is the development of uniform reusable deposit systems for the food service industry, which should result in less waste and save resources.

Edible cutlery from side streams

Some companies are developing sustainable cutlery alternatives that can be eaten. Thus, the whole spoon is utilized and nothing ends up in the trash - similar to an ice cream waffle. So these are zero-waste alternatives.

"Spoontainable", a startup from Heidelberg, Germany, wants to replace plastic in take-away catering. To do so, they rely on edible cutlery made from side streams. The founders developed a sustainable alternative to conventional plastic ice cream spoons: vegan and plastic-free ice cream spoons and stirrers made from cookie dough. In addition to flour, this is based on cocoa or oat shells. These accrue as residual material in the cocoa or baking industry. Every year, this amounts to around 700,000 metric tons of cocoa shells worldwide. At the same time, around 360 million plastic ice cream spoons are disposed of each year throughout Germany. And this after only about 4 minutes of use, however, since cocoa shells are stable and rich in fiber, they are ideal for further processing. Another consideration of the startup was that when the ice cream spoons are disposed of, the use of the residual materials does not result in renewed food waste.

The

procurement process: In principle, sufficient residual materials are produced during global cocoa production, however, not all shells can be used for further processing in the food industry. The cocoa producers who generate the residues must first clean the shells and test them for pesticides before they can be further processed for consumption. In addition, the fibers are already extracted from the shells on site and then sold to further processing companies in the baking industry. Thereby, the added value of resale compared to disposal is still given to the cocoa producer.

For production,

microscopic fibers are extracted from the cocoa or oat shells, which are residual materials in European food production. This process preserves the valuable nutrients and the dietary fiber contained in the side streams, which contributes a large part to the stability of the spoons, can thus be put to good use and resources are conserved. The dough is then processed into a stable spoon by a

baking and drying process. In principle, it is possible to produce cutlery from all fiber-rich residual and raw materials, but Spoontainable focuses on the advantages of oat and cocoa shells. During production, it is possible to work with the

expertise of cooperation partners, for example Coppenrath Feingebäck. The

machines machines as well as the automated processes do not have to be completely reinvented either, but can be built on existing technology from the baking and food industry.

Due to their composition and processing, the products remain dimensionally

stable for up to one hour. By using the cocoa shells on the one hand and the oat shells on the other, the edible spoons acquire their

flavors in a natural way. One tastes like chocolate and the other a bit more neutral, similar to oat cookies - another reason to use these residual materials for production.

In the future, Spoontainable would also like to research other products such as forks or knives. These will definitely be made from residual materials, but may only be compostable and not edible. Again, the advantage is that when the disposable products are disposed of, no plastic is released into the environment, nor is food wasted because residual materials have been processed.

Edible cutlery

"Frenvi" is a German-Indian technology company and stands for "FRiendly ENVIronment". Their mission is to produce sustainable disposable and reusable products. The company already produces edible cutlery and in the future they would like to produce cutlery and packaging that are made from sidestreams of food production.

The idea of edible cutlery has been around in India since 2012, but companies were not competitive because their production process was not scalable. Frenvi, on the other hand, sees itself as a manufacturer with the ability to scale the production process of a wide variety of products and thus focuses less on the product and marketing.

Frenvi's edible zero-waste cutlery consists of about

10% residual materials, but is based on the primary materials of

cereals and whey powder. This makes it vegetarian and, unlike the usual disposable cutlery, it is produced from sustainable and renewable raw materials. The edible cutlery remains

stable for up to one hour, depending on whether the food is liquid, solid, warm or cold. In addition, the edible cutlery is

compostable and decomposes within 30 days - if it is not eaten.

The cutlery is

more sustainable than wooden cutlery, which has been widely used to replace its banned plastic counterpart. Spoontainable and Frenvi products can be completely consumed and not a single tree has to be felled for production. In addition, wooden spoons often need to be coated, which is also bypassed with the edible alternative.

For the

production of the flat spoons, an

open baking process with common machines from the baking industry is sufficient. For the production of shaped cutlery, such as larger spoons, Frenvi's patented production technology is used. The

volume manufacturing process can produce 3D molded bodies from primary as well as secondary materials and is cost-effective as well as scalable. While the process is fully automated in the German production facility, the technical center in India is semi-automated and due to that, Frenvi creates 35 fair jobs locally. Thus, the entire production in India is scaled down and only a 15th of what is produced in Germany is manufactured.

The disposable cutlery alternative is up to

107% more resource efficient than the wooden alternative. The extraction of the raw materials as well as the production requires less water, less energy and emits

85% less CO2 emissions than the production of wooden spoons.

Compostable cutlery and packaging from side streams

In previous articles in our magazine, we have already reported products made from by-products of the food industry. These included

yarn or a designer lamp made from orange peel and

barbecue briquettes made from olive pits. And this article has already shown how ice cream spoons can be produced from leftover cocoa and oat shells.

Frenvi is also working to produce cutlery and tableware, or packaging options in the take-away or delivery sector, from fiber-based side streams to further address the single-use plastic problem. These products will not be suitable for eating, but can be

composted, making them more sustainable than plastic and wooden cutlery. On the one hand, it is not derived from petroleum like plastic and is biodegradable, and on the other hand, residual materials are recycled according to the principle of

circular economy. In this way, valuable resources are conserved. Work is being done on disposable as well as reusable alternatives, with Frenvi focusing on compostable disposable cutlery to address the weakness of reusable (deposit) systems. Again, the idea is that when the products are disposed of, there is no renewed food waste and the materials are biodegradable. In addition, the demand for these residual materials has been low so far and therefore the prices are lower.

The side streams can be beer, or tea spent grains as well as pomace from juice production. Spoons can also be made from cocoa, grain residues or nut shells. The special feature of Frenvi's production is that they can process materials that have a high

moisture content, such as wine pomace. This means that their process does not require the prior drying of the substances and they can be processed directly. Since some materials have up to 80% residual moisture, the focus is on regional processing due to logistical difficulties in transporting wet raw materials. Because this is expensive and harmful to the environment. In addition, Frenvi also works with marine raw materials such as seaweed and algae to produce tableware or packaging.

Formerly worthless residual materials are recycled into valuable new utensils. In the future, work will also be done on other packaging options made from residual materials. Frenvi also wants to manufacture products from residual materials outside the packaging sector, for example for the cosmetics industry or for medical uses.

Tableware made from palm leaves

The company

"Pleta" produces sustainable tableware from palm leaves. The plates are untreated, without chemicals and therefore biodegradable. Together with water and heat, fallen leaves of the

areca palm are pressed into plates and spoons. The plates are produced in Nepal, where people have long eaten from dried palm leaves. The production thus also has a social component, as jobs are created under fair conditions for local women and farmers.

Like the edible spoons, they only take about three months to decompose in nature. Due to the heat treatment, the tableware is temperature resistant and suitable for use in the oven, microwave and freezer. It can be cleaned and then reused. This company is also taking action against the immense use of plastic and the pollution it causes to the environment. At the same time, they use renewable raw materials that would otherwise no longer be needed.

Sustainable reusable deposit system

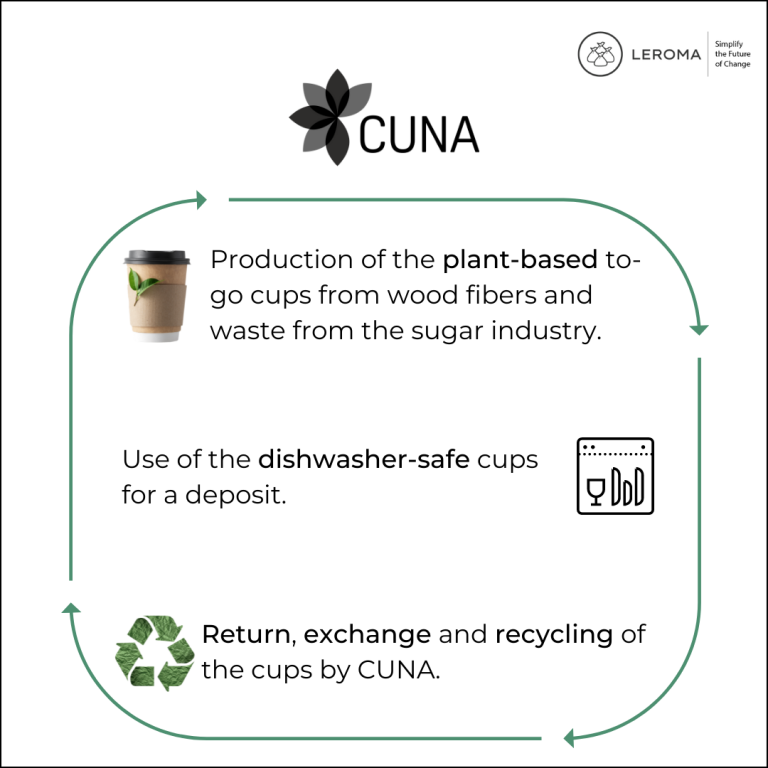

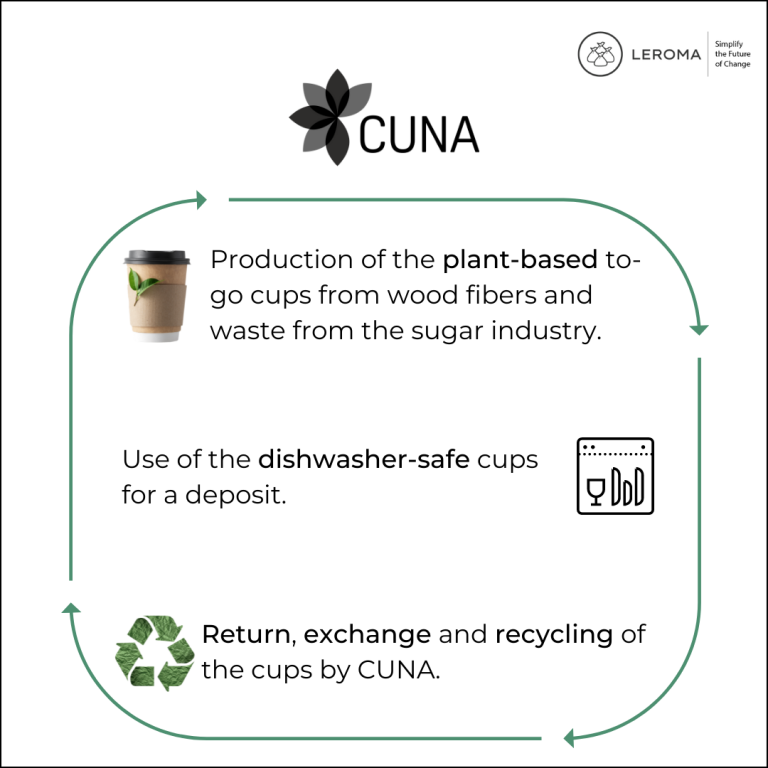

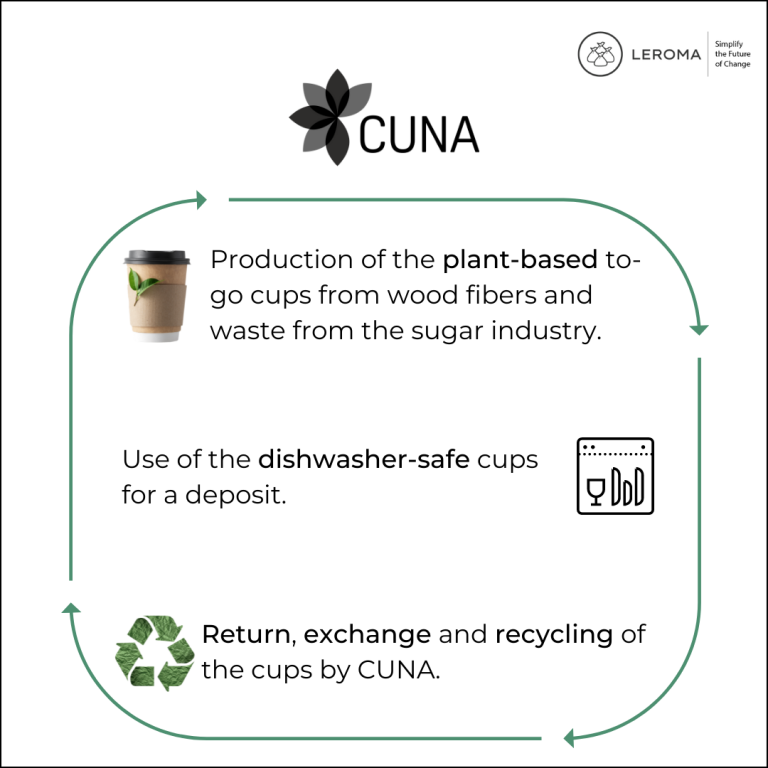

In addition to research into and use of sustainable raw materials, the spreading reusable deposit systems in the catering industry also helps to combat plastic waste. The startup

"CUNA" from Mettmann wants to contribute to a sustainable circular economy. To do so, they have not only developed a special method for producing their own to go cups, but also an accompanying reusable deposit system. Restaurateurs can participate in this without a contract. The reusable cups are

plant-based, but do not completely eliminate plastic. The plastic is derived from plants rather than petroleum and is therefore bio-based. Here, too, parts of the ingredients are side streams of food production. More precisely, they are waste from the sugar industry that cannot be further processed in the food industry, as well as wood fibers, which are also obtained from former waste. However, bio-based plastic or bioplastic does not mean that the plastic is biodegradable, but refers solely to the biological ingredients.

In order not to pollute nature and the oceans any further, the company

recycles the cups themselves and uses the plastic again in their production. However, the cups are meant to be used several times. They can be cleaned in the dishwasher and are therefore suitable for the catering industry. Only after the cups have been used and worn out for a long time are they sent back to CUNA to be recycled. In addition, CUNA exchanges the worn cups for new ones free of charge.

The material as well as the reusability save a lot of CO2. With bio-based production and the recycling system, CUNA creates a circular economy, uses renewable raw materials and takes action against plastic waste.

All these startups have one thing in common: they want to fight the waste of resources as well as plastic waste. They develop sustainable plastic alternatives from residual materials and side streams that are biodegradable or reusable. In this way, they conserve resources and contribute to a sustainable circular economy. Companies can and must develop innovative methods in the future to counter the plastic ban as well as climate change. Customer demands are also developing more and more in the direction of sustainability.

LEROMA would like to draw attention to the creative processing of valuable raw materials that are already produced in food production and the creation of sustainable alternatives to plastic and motivate companies to seize these opportunities.

Let's simplify the future of change!