Magazine

Magazine

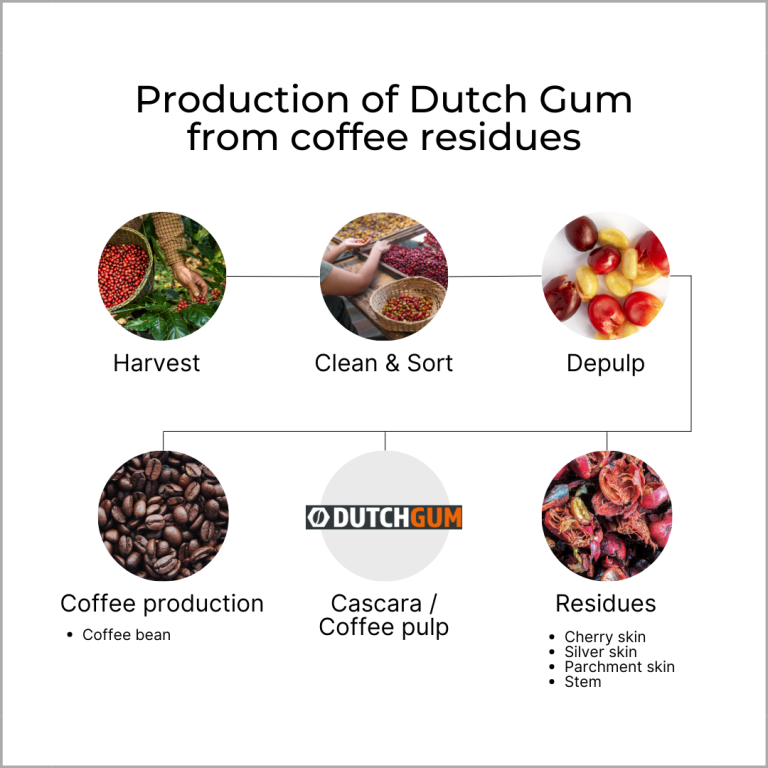

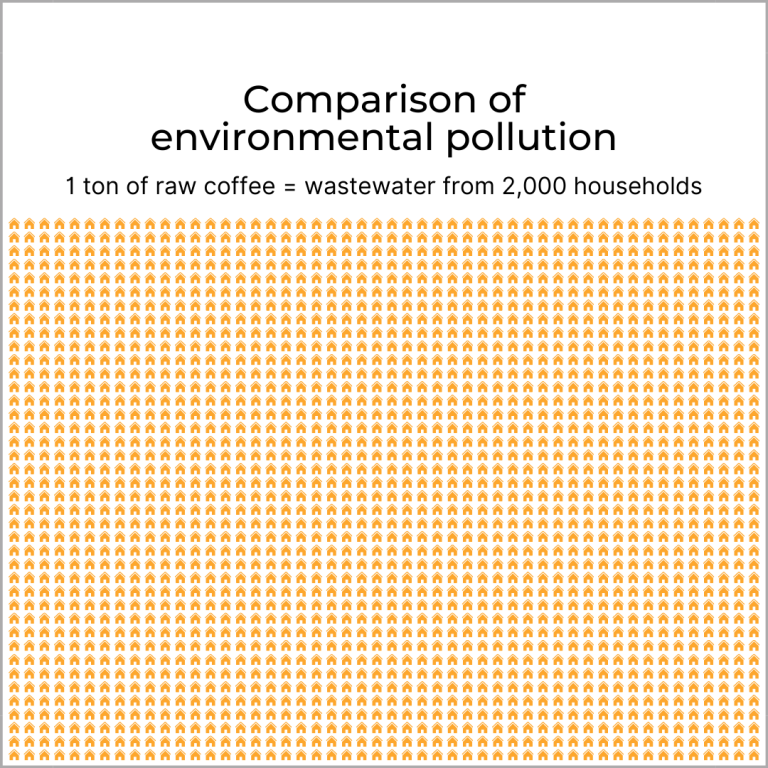

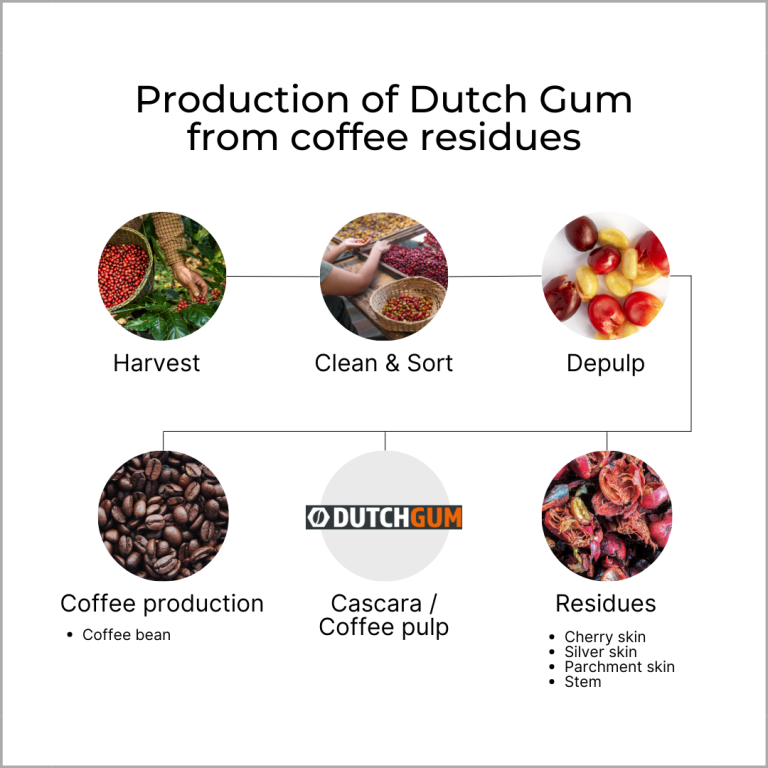

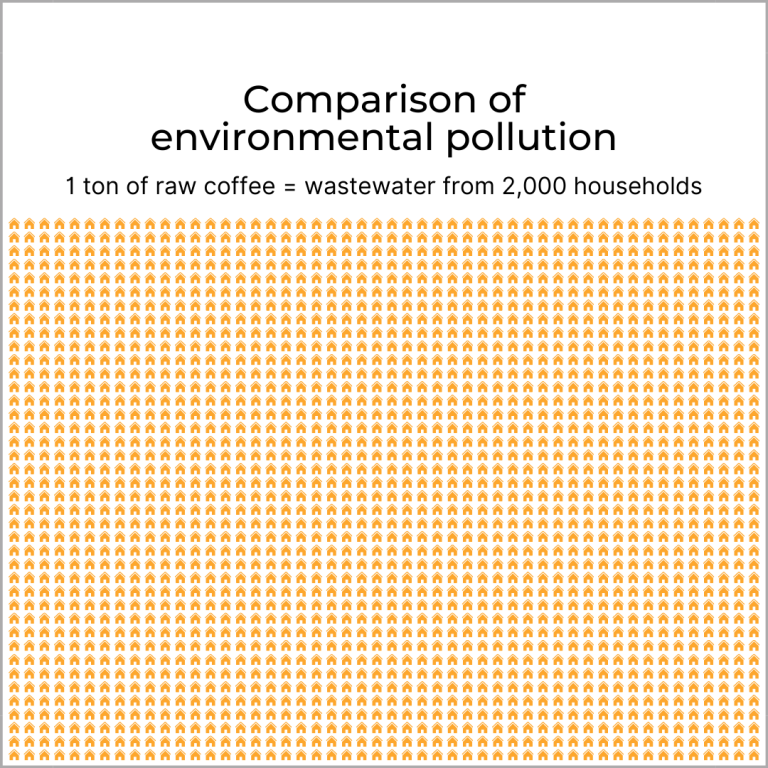

Dutch Gum: The environmentally friendly answer to the waste problem of coffee production

Dutch Gum: The environmentally friendly answer to the waste problem of coffee production

Protein, an essential component of the diet, plays an important role in building and repairing tissues in the body. Plant-based proteins are becoming increasingly popular, and oats are proving to be a remarkable source of high-quality plant-based protein. In this article, we will focus on Oat Protein and take a closer look at how oatmeal is turned into an outstanding source of protein.

Yuzu, a citrus fruit native to East Asia, has gained popularity in recent years as an innovative ingredient in the global food industry. With a unique and complex flavor profile that combines pungency and bitterness with a hint of sweetness, yuzu offers a wide range of culinary applications. This has made it a popular ingredient for food technologists looking to create innovative and exciting new dishes. From traditional uses in East Asian cuisine to modern fusion dishes, yuzu is a fruit that deserves attention.

Food additives are substances that are purposefully added to foods for technical, sensory, and nutritional reasons, such as to extend shelf life, or to sweeten and stabilize them. According to Euromonitor, about 47% of global consumers prefer natural products, and 55% of respondents look for natural characteristics when buying products. In the world, the current food trend is moving away from processed food to more natural foods with fewer additives and natural flavors. EU countries like France also make it their political agenda to produce and consume more natural foods with fewer additives.

We keep you updated about our latest news and trends for food raw materials.