What do olive stones have in common with barbecue and soccer fields?

Worldwide, about

3 million tons of olives are produced annually. The main producer and exporter of olive oil is the European Union, with Spain, Italy and Greece leading the way.

The olives are pressed into oil or sold pickled as a delicacy - often pitted. When olives are processed, a large amount of pits remain. For the former worthless by-product, there are now some innovative ideas and possibilities to process it. Thus, existing resources are reused and others are saved at the same time. Passing on and using natural raw materials contributes to a sustainable circular economy.

Grill briquettes from olive stones

The company "OlioBric" has made it its business to produce sustainable barbecue briquettes from olive stones - instead of resource-intensive tropical wood. In the production of olive oil, the whole olives, including pits, are usually pressed out. The resulting olive pomace is then used to burn out lime in a lime kiln and then pressed together with vegetable starch to make the barbecue briquettes. In this way, the already existing olive pits are processed in a sustainable and resource-saving manner and no trees have to be felled specifically for this production.

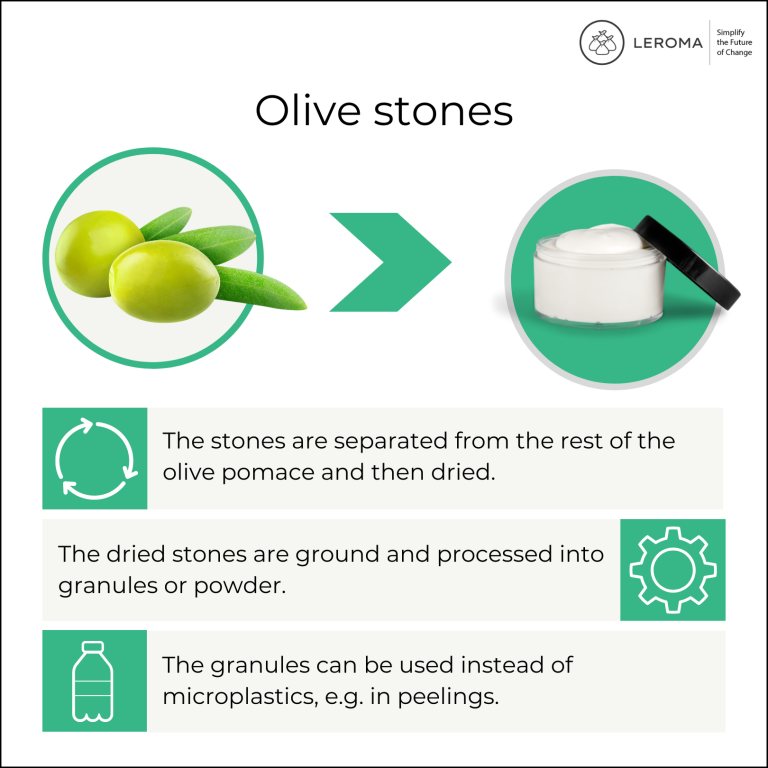

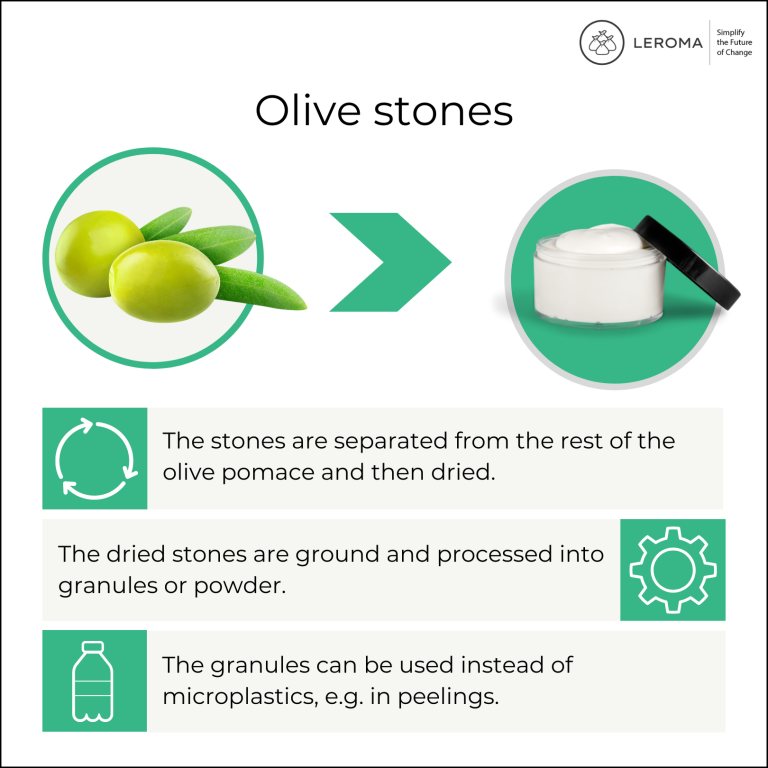

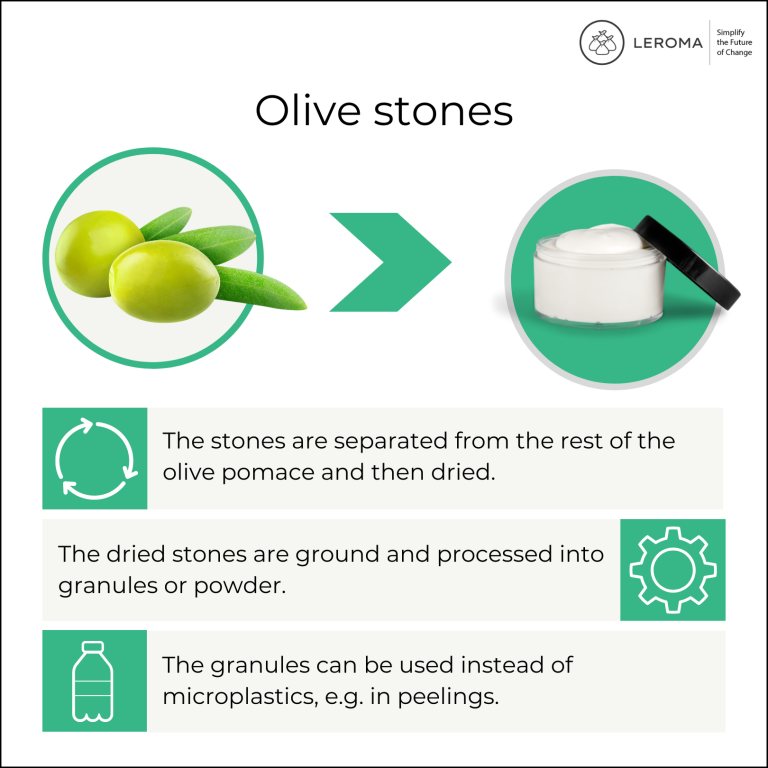

Upcycling of olive stones in various industries - as olive stone flour

In addition, the olive kernels can be processed into powder or flour. For this purpose, the seeds and the olive mass are separated by spinning and the resulting centrifugal effect. After the seed residues have been mechanically cleaned, they can be ground into high-quality flour or powder.

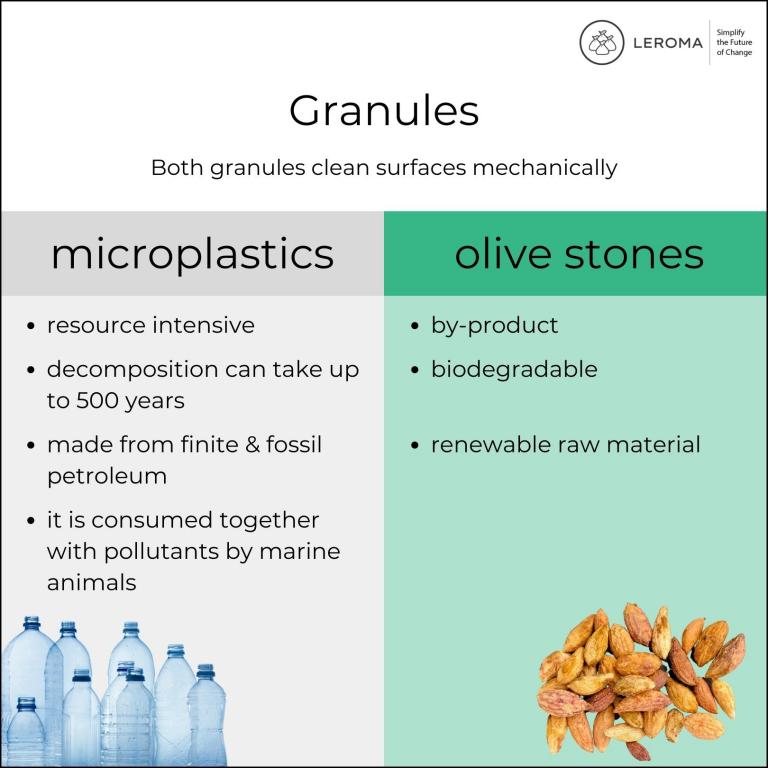

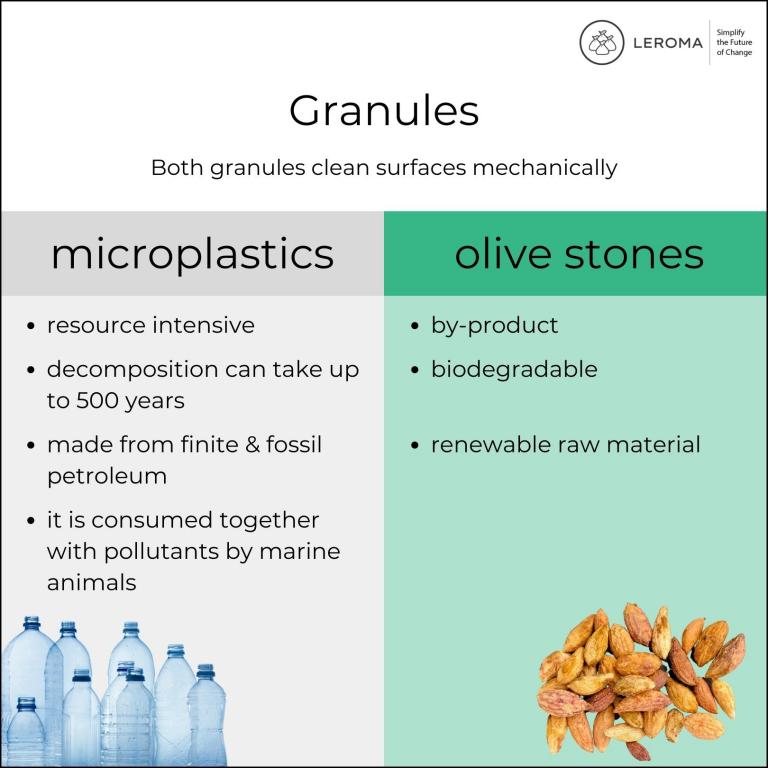

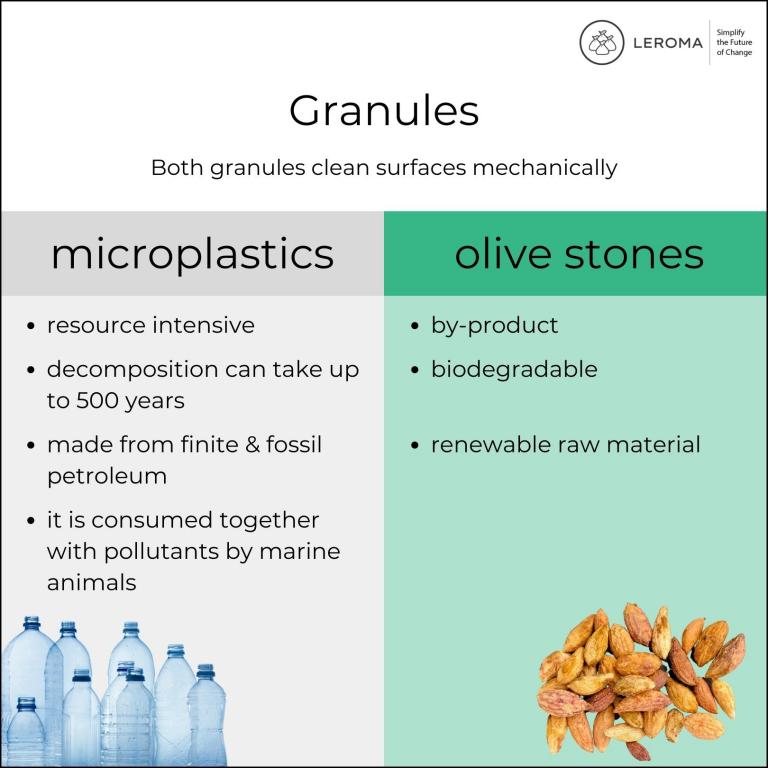

The resulting olive flour can be used as an environmentally friendly

alternative to microplastics in the cosmetics industry. The natural raw material is biodegradable rough particles that find their application in body scrubs, for example. The texture of olive stones - their stability and hardness - has the advantage of saving resources in the production of, for example, detergents or hand soaps. Both, the particles from microplastics and those from olive stones, are intended to clean surfaces mechanically. In contrast to the olive seed flour, the microplastic is very harmful to the environment. This is already evident in its production, since microplastics are made from petroleum, a finite fossil fuel. Olives, on the other hand, are a renewable resource. Moreover, the microplastic enters the oceans through drains, where it takes up to 500 years to decompose.

Due to its positive properties, olive seed powder can be used as a

superfood ingredient in a wide variety of foods. It contains many carbohydrates and easily digestible fiber, and has no allergens such as gluten. In addition to its health-promoting properties, it helps give products the desired texture and can be used as a natural thickener. Olive pit flour can be used not only in food processing, but also in animal feed production, as a substitute for fish or bone meal in vegetarian or vegan pet food.

How can olive pits and artificial turf be combined?

Olive pits can also be used as a sustainable option in the production of artificial turf pitches and playing fields. Artificial turf is criticized because it consists of different plastics that are processed together to such an extent that they can hardly be separated from each other during disposal, or only with a great deal of effort. Artificial turf usually consists of a polypropylene ground, the "blades of grass" of silicone-coated fibers and a microplastic granulate that is dumped between the blades. For this reason, the disposed artificial turf cannot be recycled and then reused, instead it goes to incineration.

At least for the microplastic, some artificial turf manufacturers have developed an alternative solution. In this case, sand or granulated olive pits can replace the conventional plastic that is harmful to the environment and our health. The use of microplastics is criticized because the synthetic polymers end up in the environment and not only does it decompose with great difficulty but it also takes a long time. The use of olive pit granules is said to offer the same stability and playing comfort as the conventional microplastic.

Therefore, not only is the olive stone being recycled as a by-product of olive oil production, but an environmentally harmful material is also being replaced by a natural one.

Energy from olive stones

Even in ancient times, dry olive residues were burned in the mediterranean region for heating or cooking. Still today, olive pits can be burned as a former by-product to generate heat, electricity, biogas and biofuel, just like coffee grounds, grape stalks and rice husks. Incineration represents the final step in the value chain. Again, the crushed olive pits are first separated from the remaining pomace and then dried. The remaining pomace is often further processed into frying oil or oil for canning, and the dried pits are sent to incineration. The olive biomass releases a considerable amount of energy when burned and its calorific value far exceeds that of wood waste. The energy produced can be directly used in the olive oil production process.

Since incineration is

downcycling, the other options presented should be approached preferentially. Nevertheless, as a final step, it makes sense to create added value from waste products that cannot be recycled or upcycled by recovering them for energy.

Biomass is the most important renewable energy source in Germany. If the biomass is obtained directly from by-products or residual products, the process of energy generation becomes even more sustainable. Generating energy from biomass or alleged waste products is a contribution to establishing an ecological and sustainable circular economy. The combustion of residual and waste products is thus considered to have great potential for future energy production in Germany.

Olive stones are not a

waste product, but a

sustainable and versatile resource. It can be used in various industries as a sustainable material for further processing. LEROMA would like to draw attention to these opportunities and possibilities for the valorization of by-products as well as surpluses and encourage companies to counteract food waste and thus motivate them to a sustainable circular economy.

Let's simplify the future of change!